Safety and quality

Precision with state-of-the-art crack testing and demagnetization technology.

Safety and quality

Precision with state-of-the-art crack testing and demagnetization technology.

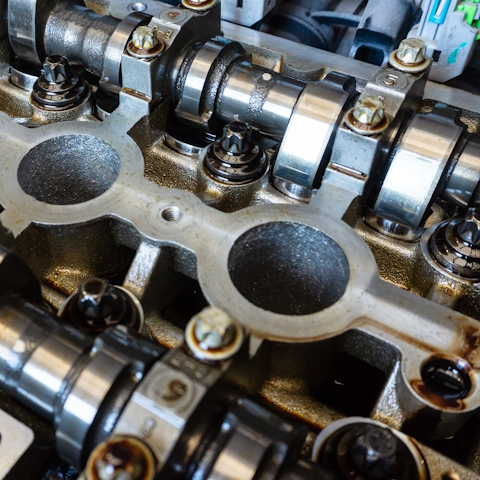

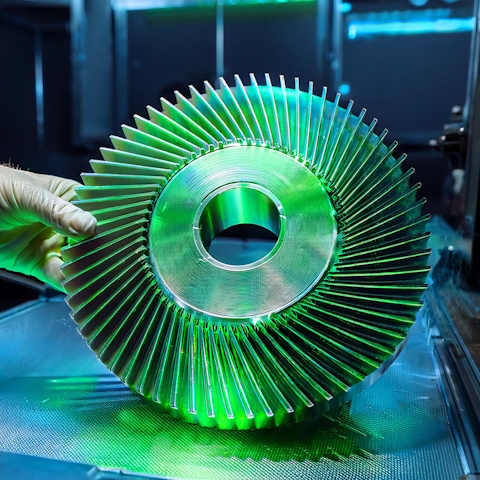

Reliable technology for your components.

Many companies struggle with outdated testing methods, residual magnetism, and strict quality demands. Tight deadlines and limited resources make it tough to find efficient solutions. That’s where we come in. With cutting-edge technology and expert know-how, we deliver precise testing, top-notch demagnetization, and seamless processes.

Was wirklich zählt?

Ihre Effizienz, Ihre Qualität und Ihr Erfolg – wir kümmern uns um den Rest.

Services

Our magnetic particle crack detection and demagnetization services ensure seamless and efficient testing, eliminating unnecessary frustration during complex processes. We provide precise, reliable solutions that maintain the integrity of your components. With state-of-the-art technology and deep industry expertise, we help you optimize production workflows and meet the highest quality standards.