Technologies for Magnetic Particle Testing (MT Testing) and Demagnetization of Steel Components

DC Pulse Technology

Magnetization through DC Pulses

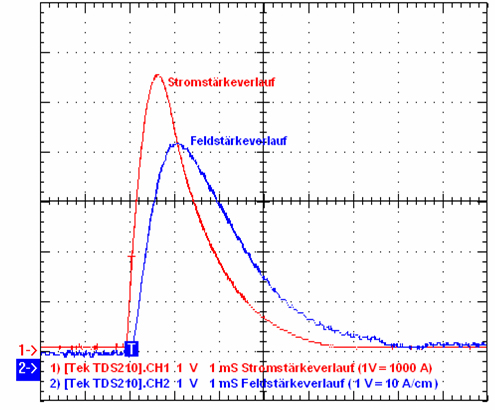

Through capacitor discharge, very high pulse currents are generated for a few milliseconds (fig. 1). The DC pulses generate magnetic field pulses within the steel components which then leak through the surface faults such as cracks in the form of stray fields.

These stray field pulses exert a strong, abrupt pull on the ferric oxide particles contained in the test medium, causing them to accumulate at the leaking stray fields and become visible under UV light.

Your Benefits as a User: :

- sharp, clear crack indications

- quick MT test results within approx. 3 seconds

- easy handling; high-performance, yet light devices

- llow power consumption, low operating expense

- easy handling of components; no clamping necessary

Demagnetization through DC Pulses

Steel components can be demagnetized permanently through DC pulses of decreasing intensity and alternating polarity.

(Image 1) Current and field strength curve of a direct current pulse during a capacitor discharge

Direct Current Flow

Magnetization through 4 Pole Method

(Testing and Demagnetization)

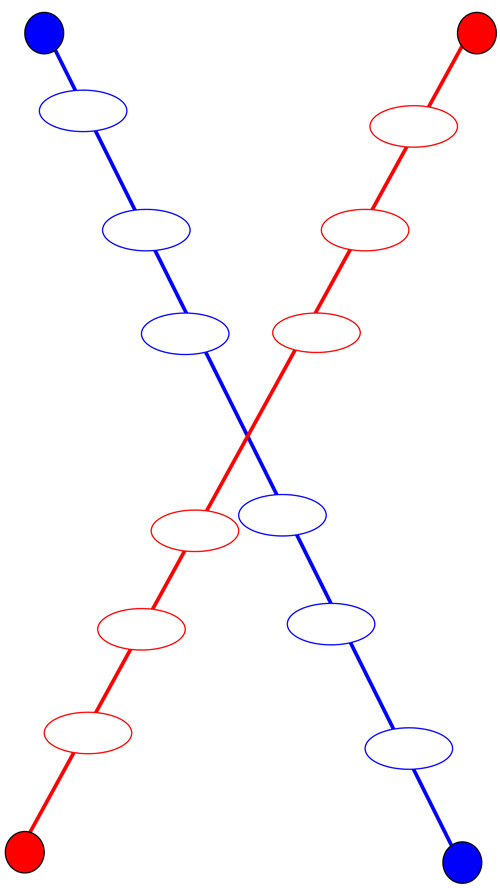

With the 4 Pole Method, test currents alternately flow through the component in a crosswise manner. Magnetic fields build up along the current paths. The stray fields which leak from the cracks cause a clearly defined accumulation of magnetic powder particles, ensuring precise, clear crack indications.

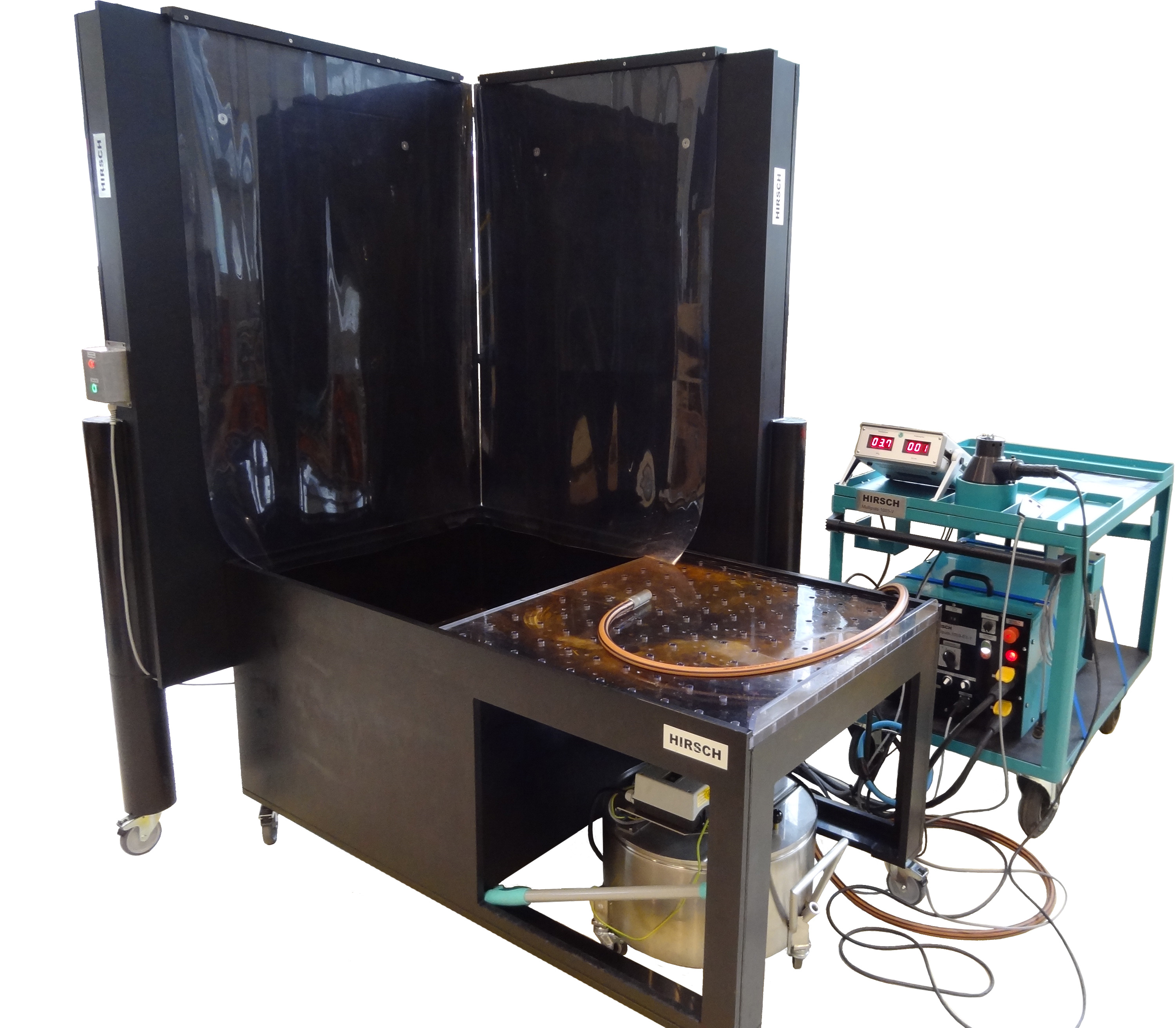

The 4 Pole Method is most suitable for planar components (fig. 2) and is used for MT testing as well as demagnetization.

Combined Method

Magnetization through Combined Method

(Testing)

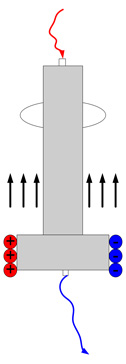

With this method, the component is magnetized through a combination of direct current flow and coil magnetization. The DC pulses generated by the MT testing device alternately flow through the component (or a coil wrapped around it) via test leads and magnetic poles. The stray fields which leak from the cracks cause a clearly defined accumulation of magnetic powder particles, ensuring precise, clear crack indications.

The combined method is most suitable for rotationally symmetrical components and is used for MT testing.

Contact-Free Method

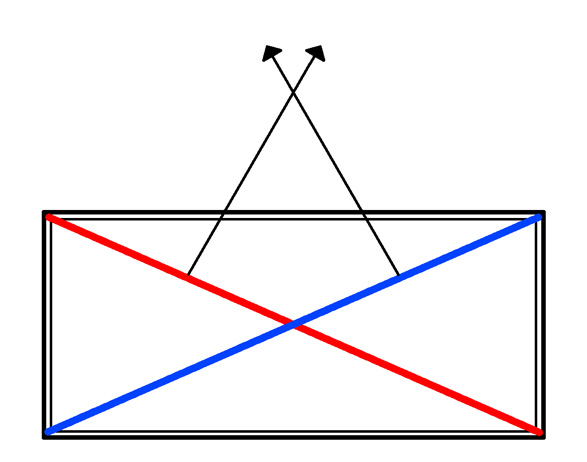

The contact-free method is most suitable for compact components of various geometry. It is used for MT testing as well as demagnetization.